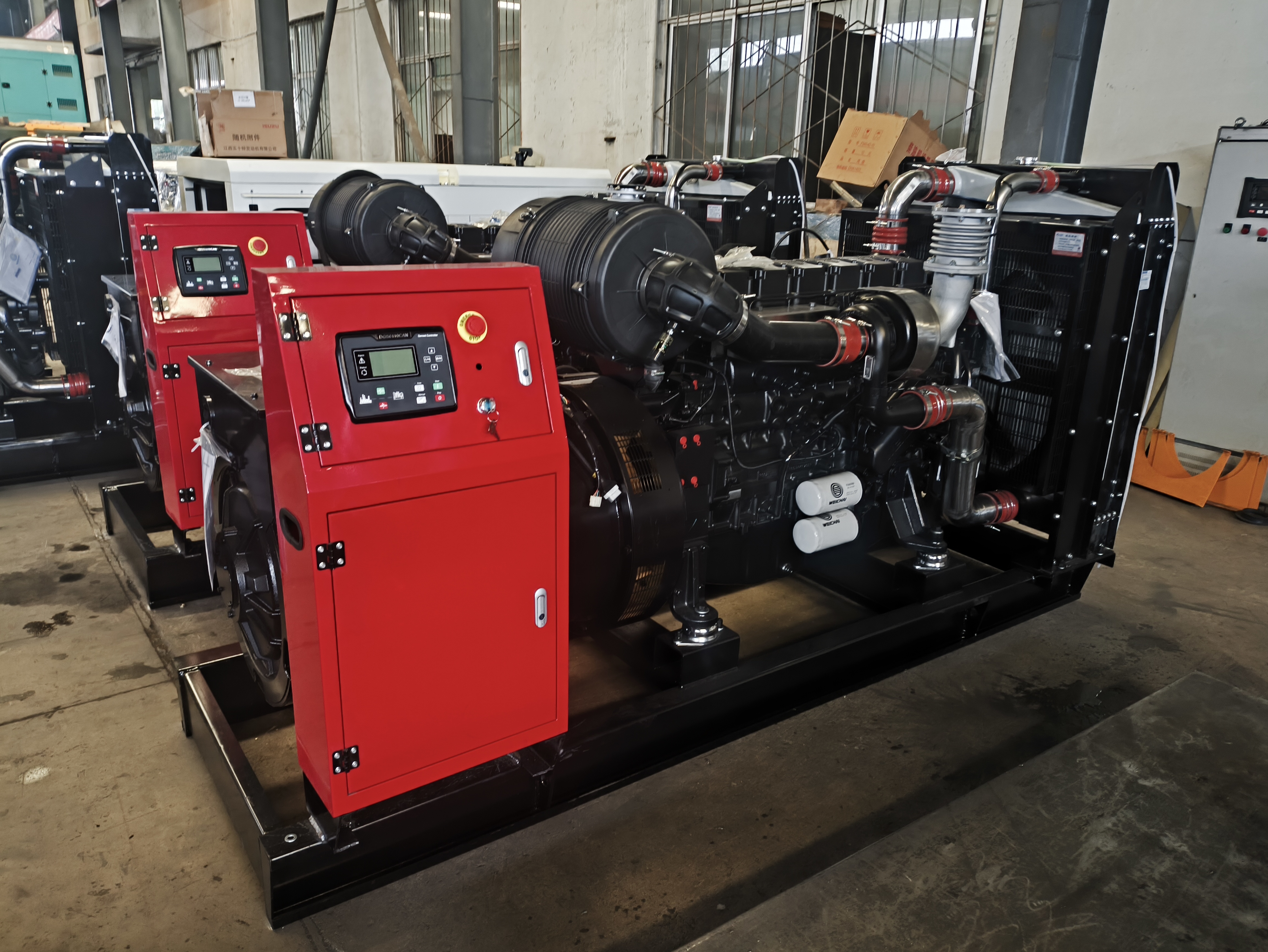

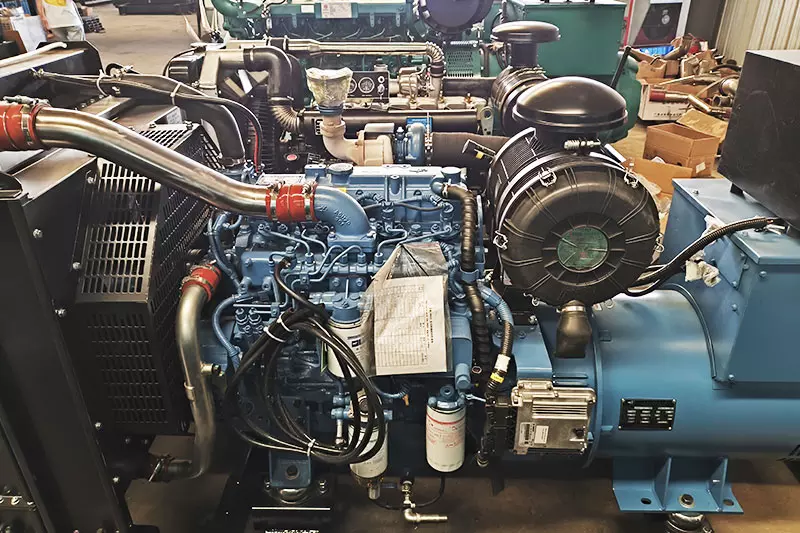

Generator set operation handling after running for a period of time

Release Date:

2025-07-22

After the generator set has been running for a period of time, regular inspections must be carried out.

After the generator set has been running for a period of time, regular inspections must be carried out. For long-running units, checks should be done every 6-8 hours. For standby units, another inspection should be performed after shutdown. The inspection areas can include the following aspects: lubricating oil sludge, air filter blockage indicator, coolant level, radiator and external ventilation conditions, engine drive belt assembly, fuel supply status, etc. After every 50 hours of operation, the water accumulated in the oil-water separator should be drained and the starting battery electrolyte level checked; after 200-300 hours of operation for new units, valve clearance and injectors must be checked; after 400 hours of operation, the drive belt needs to be inspected and adjusted, replaced if necessary, radiator fins cleaned, and sludge in the fuel tank drained; after 600 hours or at least every 12 months, lubricating oil and oil filters must be replaced. The frequency of oil changes depends on the quality of the lubricating oil, sulfur content in the fuel, and the generator set's oil consumption. After 800 hours, the oil-water separator and fuel filter should be replaced, the turbocharger checked for leaks, intake pipes inspected for leaks, and fuel lines cleaned; after 1200 hours, valve clearance should be adjusted; after 2000 hours, air filters and coolant should be replaced, and the radiator fins and water passages thoroughly cleaned; after 2400 hours, injectors should be checked, the turbocharger thoroughly inspected and cleaned, and a comprehensive inspection of the engine equipment performed.

Related News

"Survive by Quality, Develop by Technology" is the corporate culture of Benma Power Company