Structural Analysis of Diesel Generator Sets

Release Date:

2025-07-22

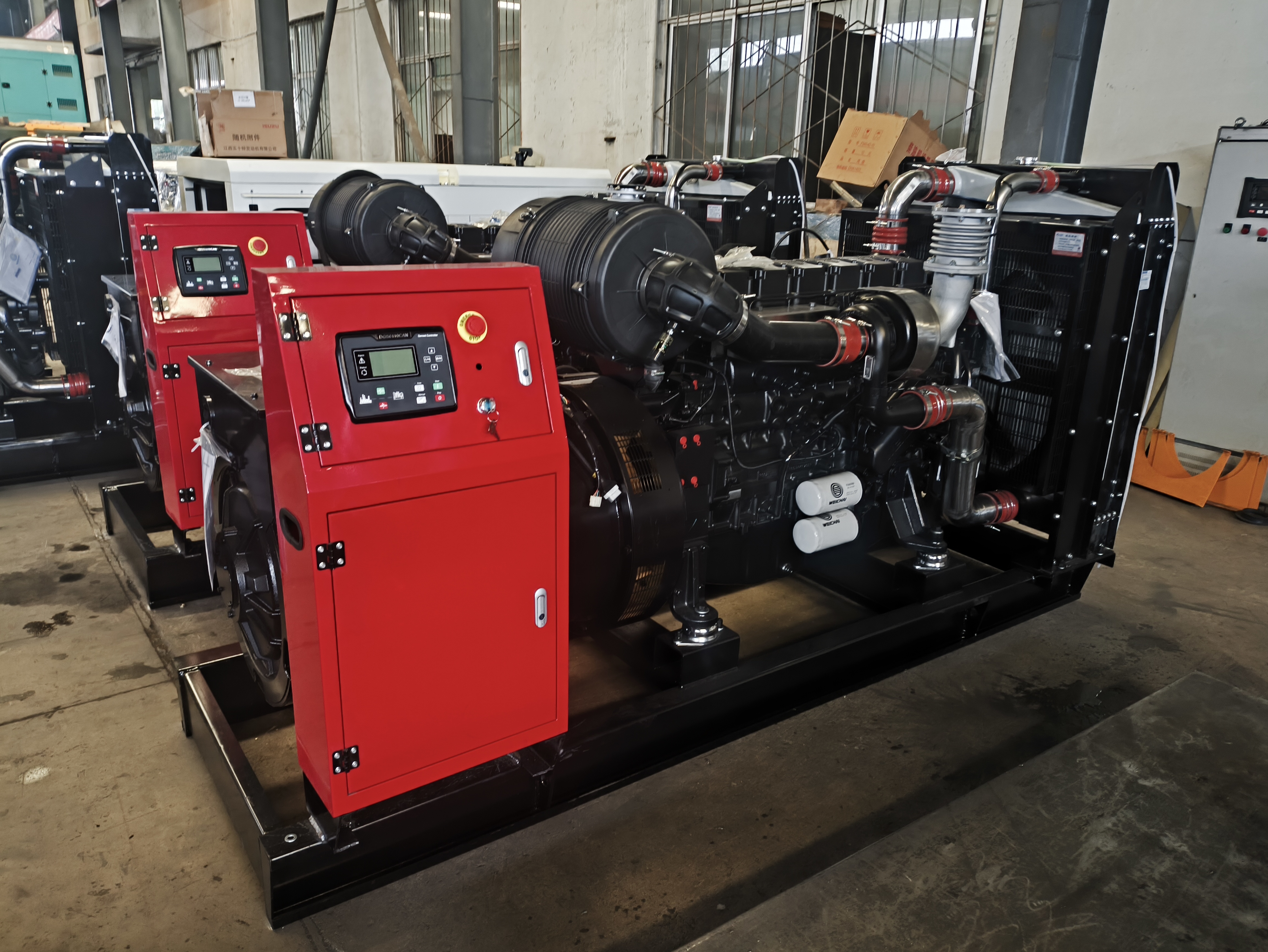

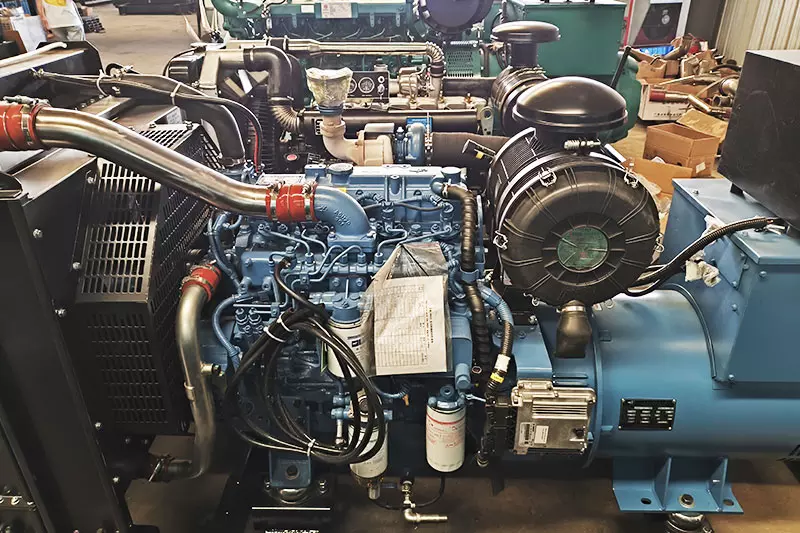

A standard diesel generator set mainly consists of three parts: the diesel engine, the generator, and the control system.

A standard diesel generator set mainly consists of three parts: the diesel engine, the generator, and the control system. There are two connection methods between the diesel engine and the generator: one is flexible connection, which uses a coupling to connect the two parts; the other is rigid connection, which uses high-strength bolts to connect the generator's rigid connection plate to the diesel engine's flywheel. Rigid connections are more commonly used in diesel generator sets on the market. After the diesel engine and generator are connected, they are installed on a common base frame, then equipped with various sensors for protection, such as water temperature sensors. These sensors visually display the operating status of the diesel engine to the operator. With these sensors, an upper limit can be set; when this limit is reached or exceeded, the control system will issue a pre-alarm. If the operator does not take action at this point, the control system will automatically shut down the unit. This is how the diesel generator set achieves self-protection. Sensors receive and feedback various information, but it is the control system of the diesel generator set that truly displays this data and executes protection functions. The control panel is generally installed on the generator and is called a backpack control panel; some are independently placed in the control room and are called split control panels. The control panel connects to the generator and sensors via cables, displaying electrical parameters and diesel engine operating parameters respectively. Additionally, the generator set includes a chassis, coupling, radiator, and fuel tank; some are also equipped with a silencer and enclosure.

Related News

"Survive by Quality, Develop by Technology" is the corporate culture of Benma Power Company